BLUETRACE

Building a configurable shellfish tag design & system

Challenge

The shellfish and seafood tags we custom printed with our system had one common compliance standard, but many implementations in our system. The cost of designing and maintaining special tags per customer was overwhelming our team, customers, and regulators.

Goal

Build a configurable reusable system that ensured that legally-required state and federal Key Data Elements (KDEs) for shellfish tags and seafood labels are printed in a compliant manner

Make sure the tags and labels looked legible and attractive, because many customers viewed these are marketing.

Constraints

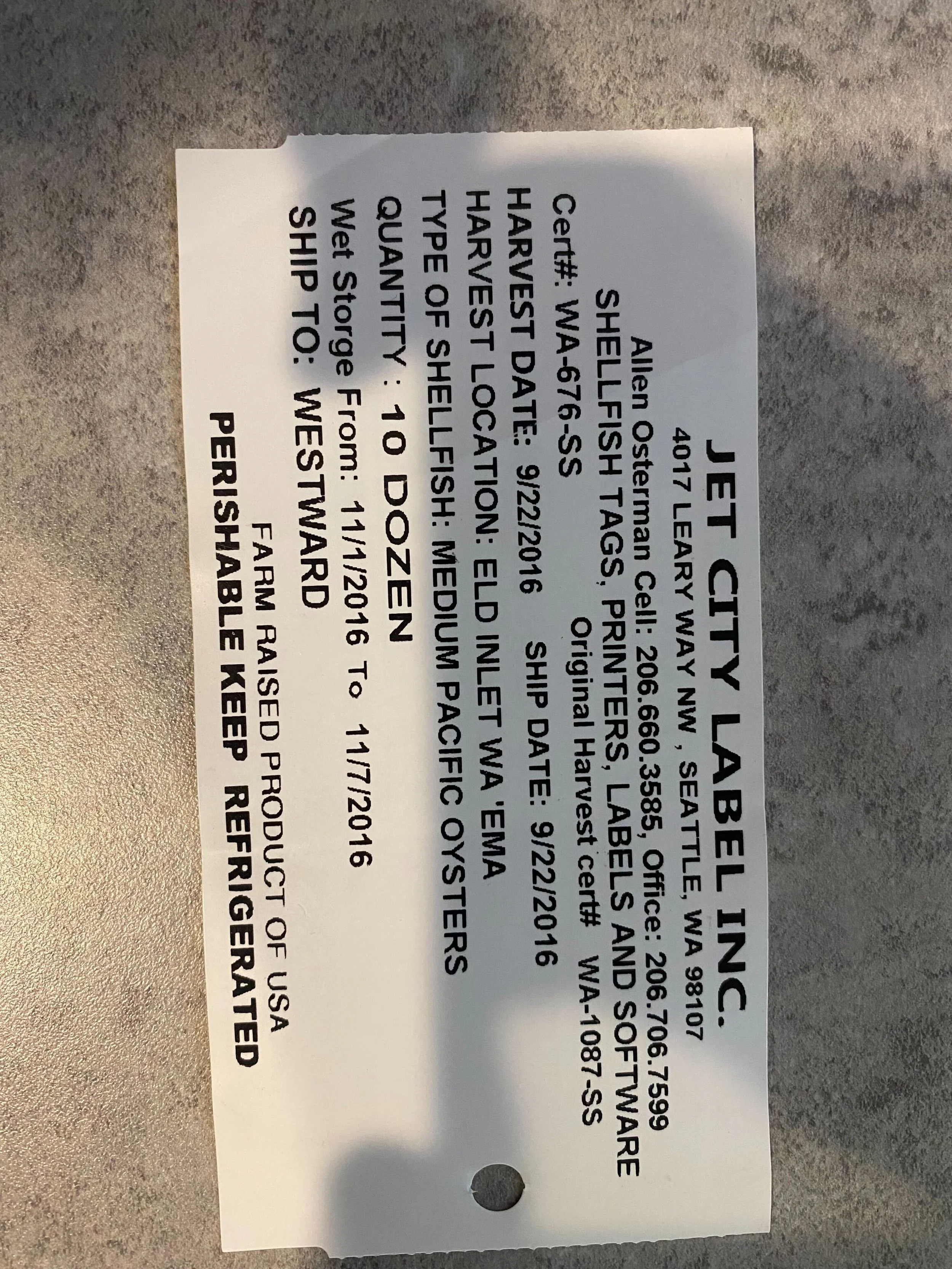

Tags have to be printed on set sized “paper” medium (3x7 in)

Printers can only print in black and white, low resolution.

Printers must print quickly: 60 tags per minute.

“On printer” layout and rendering system is extremely primitive compared to industry standard digital printing.

Need to allow for hole punches and clearance areas.

All tags are approved by state regulators who have their own special requirements for KDEs that extend the federal mandate.

Producers include their own KDEs for inventory tracking

Producers require special callout areas for operational reasons.

Multiple tag types with their own requirements: Harvest, Dealer, Bulk, Wet Storage.

Tag design needs to be setup per customer in the sales cycle.

Process

Starting with a one-size-fits all tag design

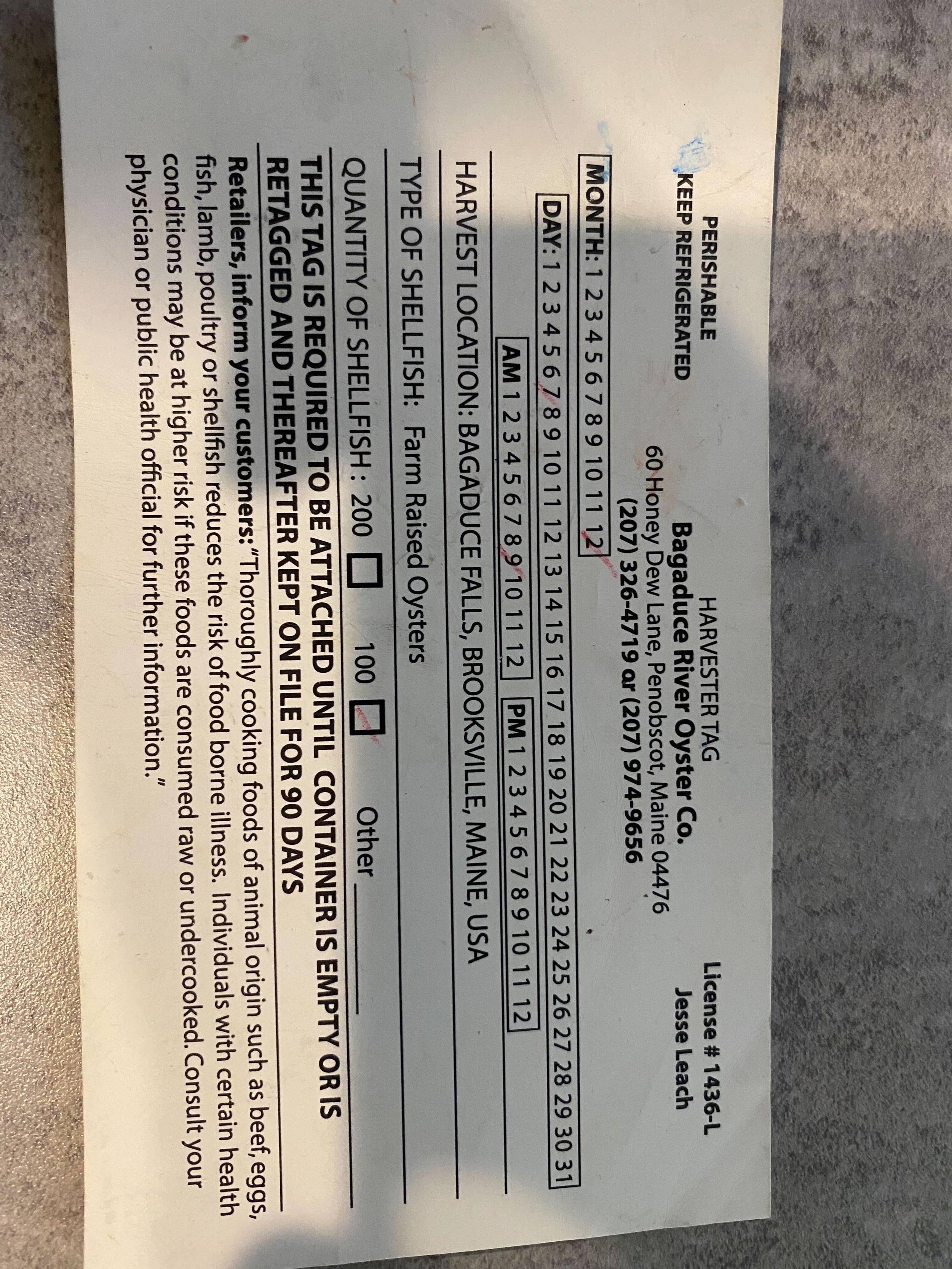

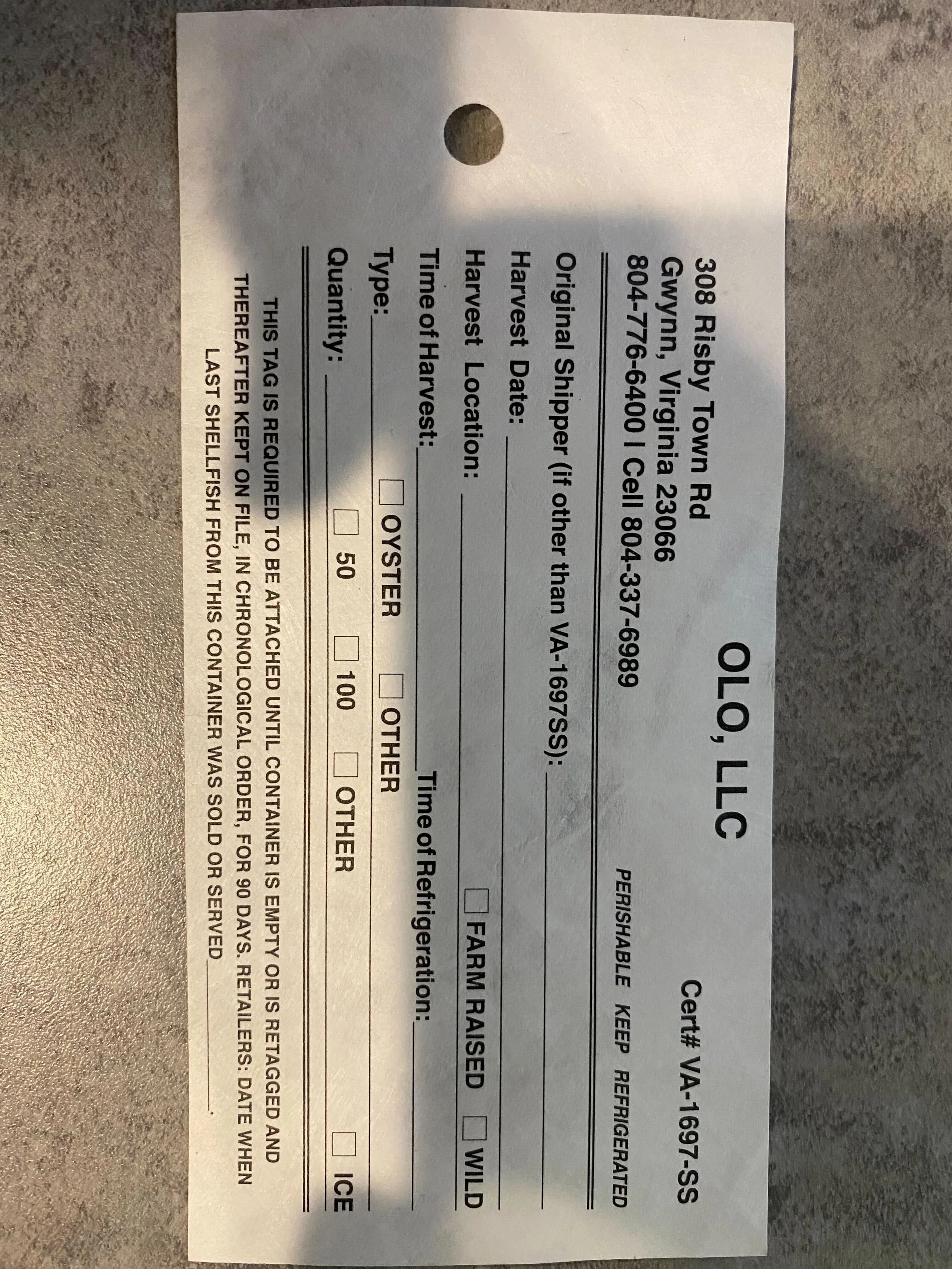

We began with a simple, one-size-fits-all shellfish tag design that was hard-coded to meet a handful of known regulatory requirements. It worked for our first customers, but as our client base grew across different states and business types, it quickly became clear that compliance alone wasn’t enough.

Regulators had unique expectations, and customers wanted more flexibility to reflect content that their operations uniquely cares about. Within a year, we realized the static system couldn’t scale, setting the stage for a more dynamic, adaptable approach to tagging.

Tag content hell and printer limitations

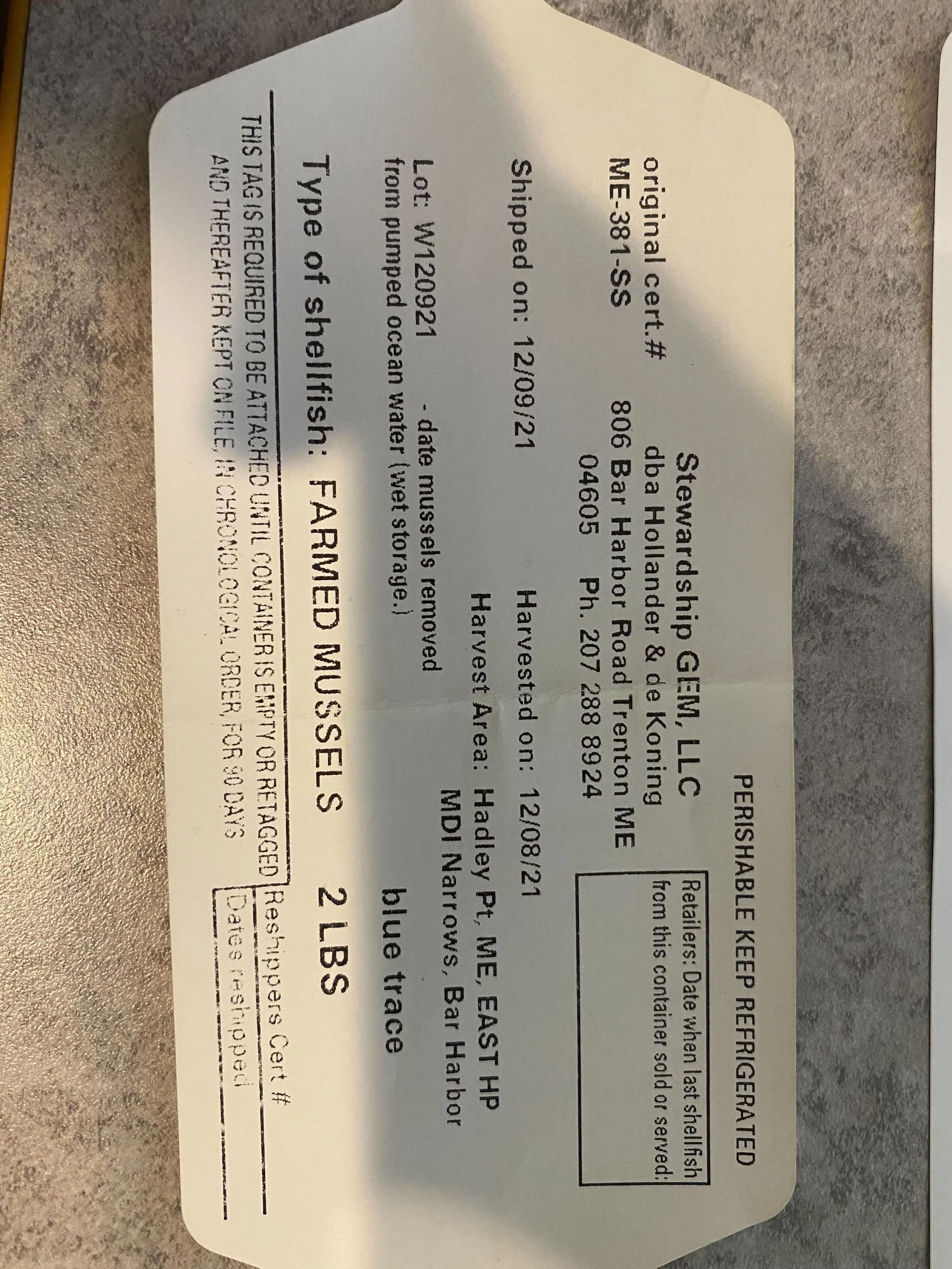

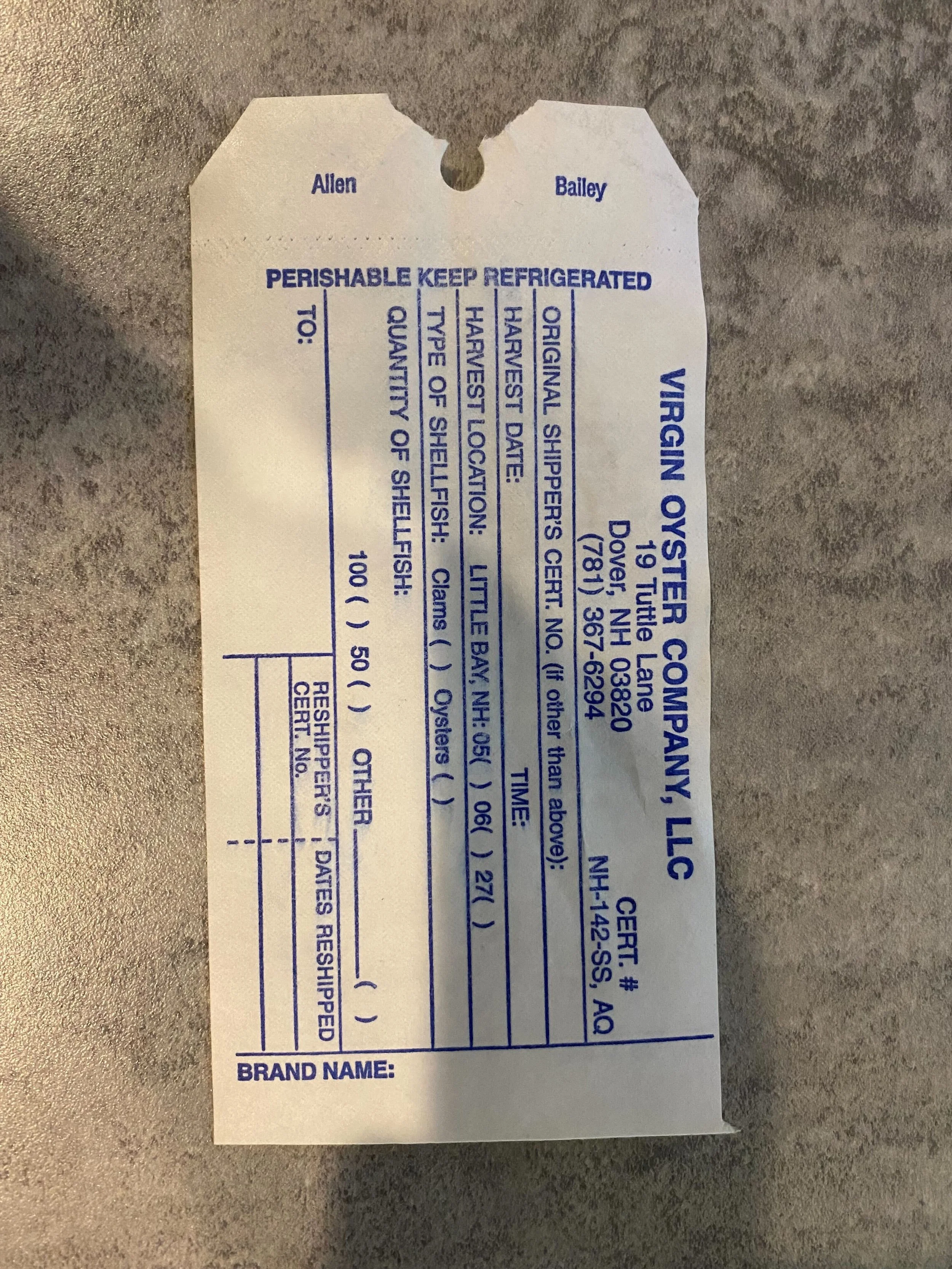

We studied hundreds of handwritten and printed tags, analyzed customer practices, and mapped out the common content types. There was a stabl-ish combination of content

Company metadate + cert numbers

Required fields

Random fields the business liked

Things that people thought were required but actually weren’t

Legal text

Our one-size-fits-all approach wasn’t the only obstacle. Legacy printers could only handle raw text with almost no styling or layout control: no fonts, no alignment, no images. After exploring dead ends with the manufacturer’s SDK, we took a different path.

We engineered a system that built each tag virtually in HTML and CSS—complete with precise spacing, font family and weights, and other design elements—then rendered it as a bitmap image. By sending that image to the printer, we unlocked full creative control over tag design. This breakthrough transformed an antiquated limitation into a pretty flexible, scalable solution.

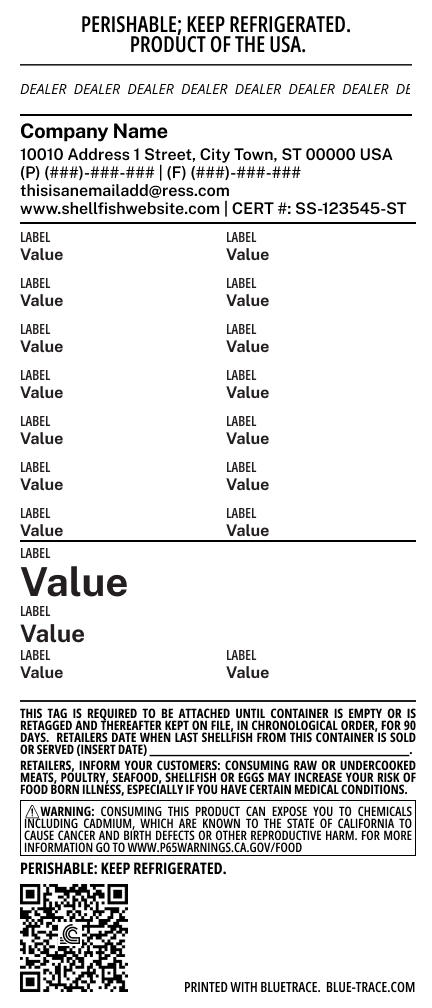

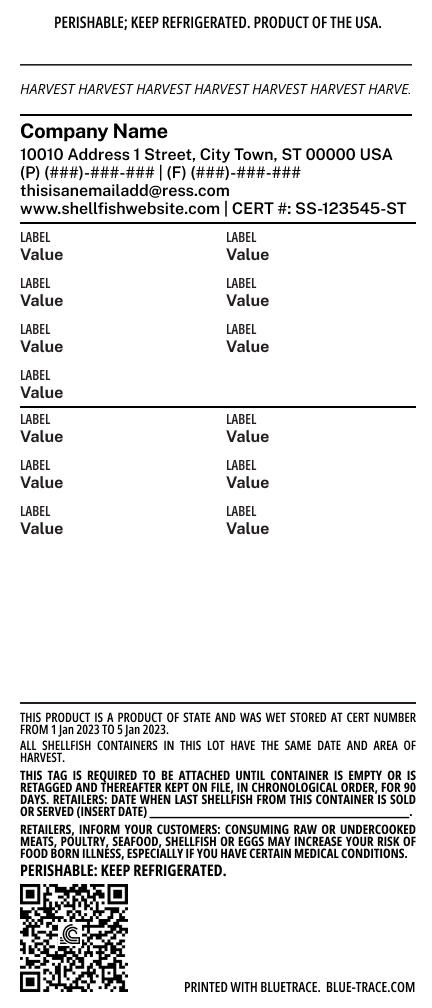

Designing a smarter tag system

With new printing flexibility unlocked, the challenge shifted to content: balancing what customers wanted on their tags with federal and state requirements. The result was a structured information architecture—flexible enough to meet diverse needs, but constrained enough to ensure compliance. We designed a modular tag system with clearly defined sections:

Business metadata at the top

Configurable required KDE blocks

Configurable call out KDE blocks for non required data

Legal text block

Optional barcodes for retail.

By combining these configurable components, we created a system that could generate virtually any tag type, tailored to each customer while staying compliant.

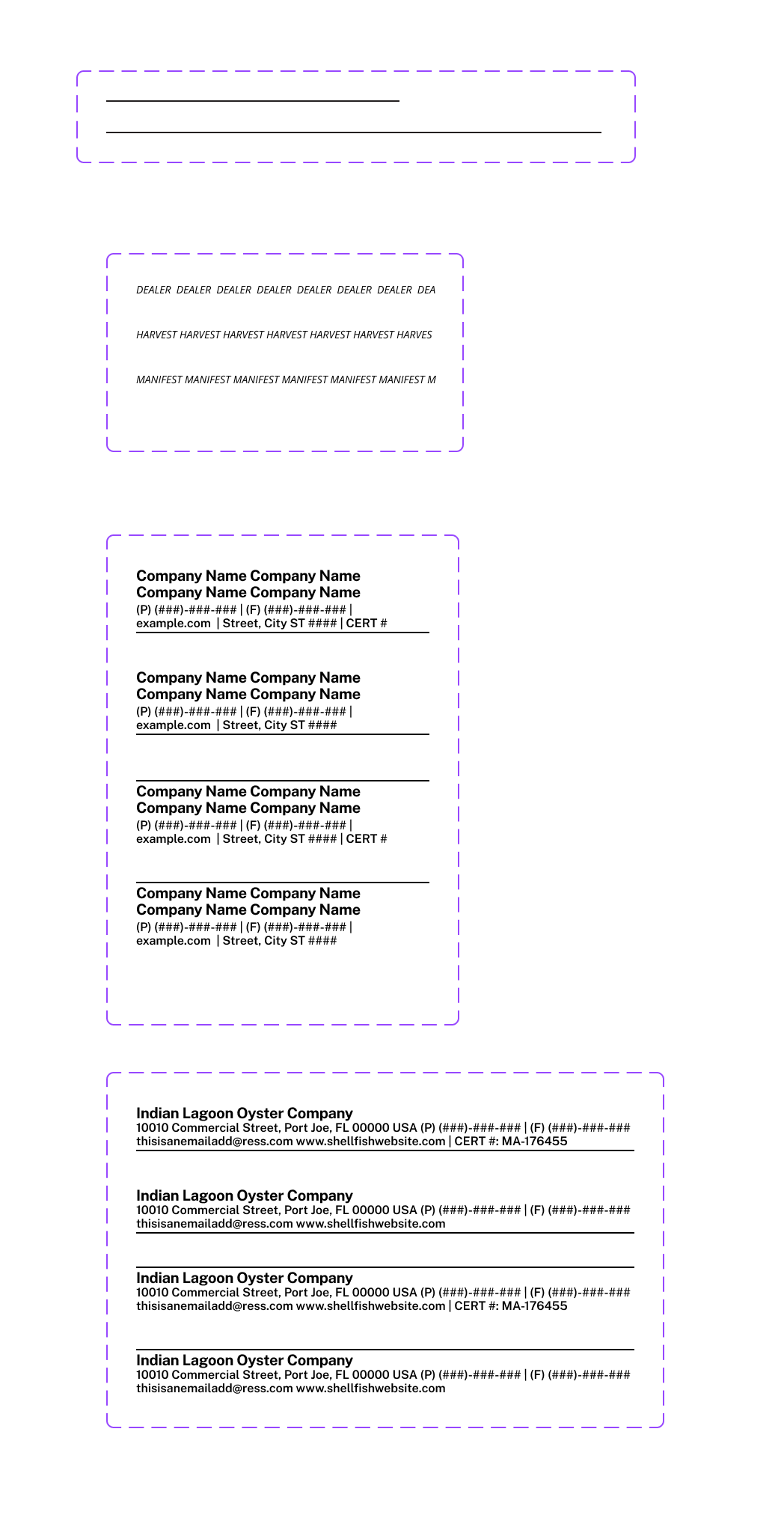

Scalable Design “CMS” with Figma “TagKit”

We translated our modular tag system into a responsive Figma kit that carried all the business logic for layout. This let us quickly mock up tags for customers or regulators, while also ensuring that any future updates happened once—at the system level—so every tag, past and future, inherited the improvements. No one-offs, just scalable, systematic design.

Results

Custom tag work dropped to zero, new system accommodated all potential configurations.

All existing customers moved to the new system.

“PaperKit” system in Figma made it easy to adapt or improve CMS in the future (e.g. new legal text)

Qualitative feedback on new tag design was solid because we could use font family, size, style of our choosing.